construction

Shell & Tube Heat Exchanger

High-Integrity Solutions

Shell & Tube Heat Exchanger

At BESB, we specialize in the fabrication of Shell and Tube Heat Exchangers tailored for both onshore and offshore facilities. Our commitment to quality extends to ensuring compliance with international codes and standards such as TEMA, ASME, ISO, and API. By adhering to these stringent guidelines, we guarantee that our heat exchangers meet the highest industry standards for safety, reliability, and performance, regardless of the operating environment.

Service Information

Shell and Tube Heat Exchangers are vital components used for efficiently transferring heat between fluids in various industries. At BESB, we specialize in fabricating these exchangers for both onshore and offshore facilities, ensuring compliance with international codes and standards such as TEMA, ASME, ISO, and API.

Completed Projects

Our completed projects stand as testaments to our expertise and dedication in delivering high-quality solutions to the oil and gas industry. Each project reflects our commitment to innovation, safety, and client satisfaction.

Reboiler Exchanger

Dimension: OAL 10572 x 2200 ID x 1800 ID

Weight: 43,670 KG

Material: SA 516 GR.70 + SS410 CLAD

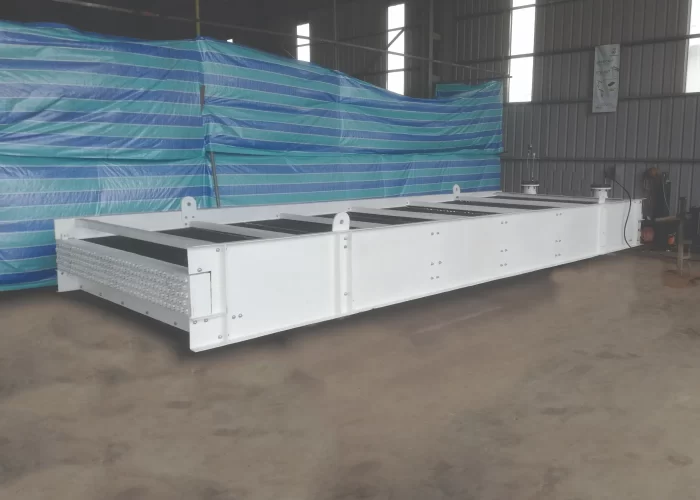

Air-cooled Heat Exchanger

Dimension: OAL 8265 X 63.5 FIN OD

Weight: 6,383 KG

Material: SA 516 GR 70

Retubing 8 Unit Of Air Finned Cooler

Dimension: OAL 10594 X 82.55 FIN OD

Weight: 55,001 KG

Material: SA 516 GR 60

EB-1304 Superheater

Dimension: OAL 3310 X I.D 600

Weight: 1,800 KG

Material: SA 240 GR 304L

Thermosyphone Reboiler

Dimension: OAL 5134 X I.D 1000

Weight: 9,400 KG

Material: SA 516 GR 70N

Vaporiser Package Heat Exchanger

Dimension: OAL 6782 X I.D 1400 X I.D 560

Weight: 5,900 KG

Material: SA 516 GR 70